Our experience in engineering and manufacturing enables us to execute industrial projects with precision, clear timelines, and proven results.

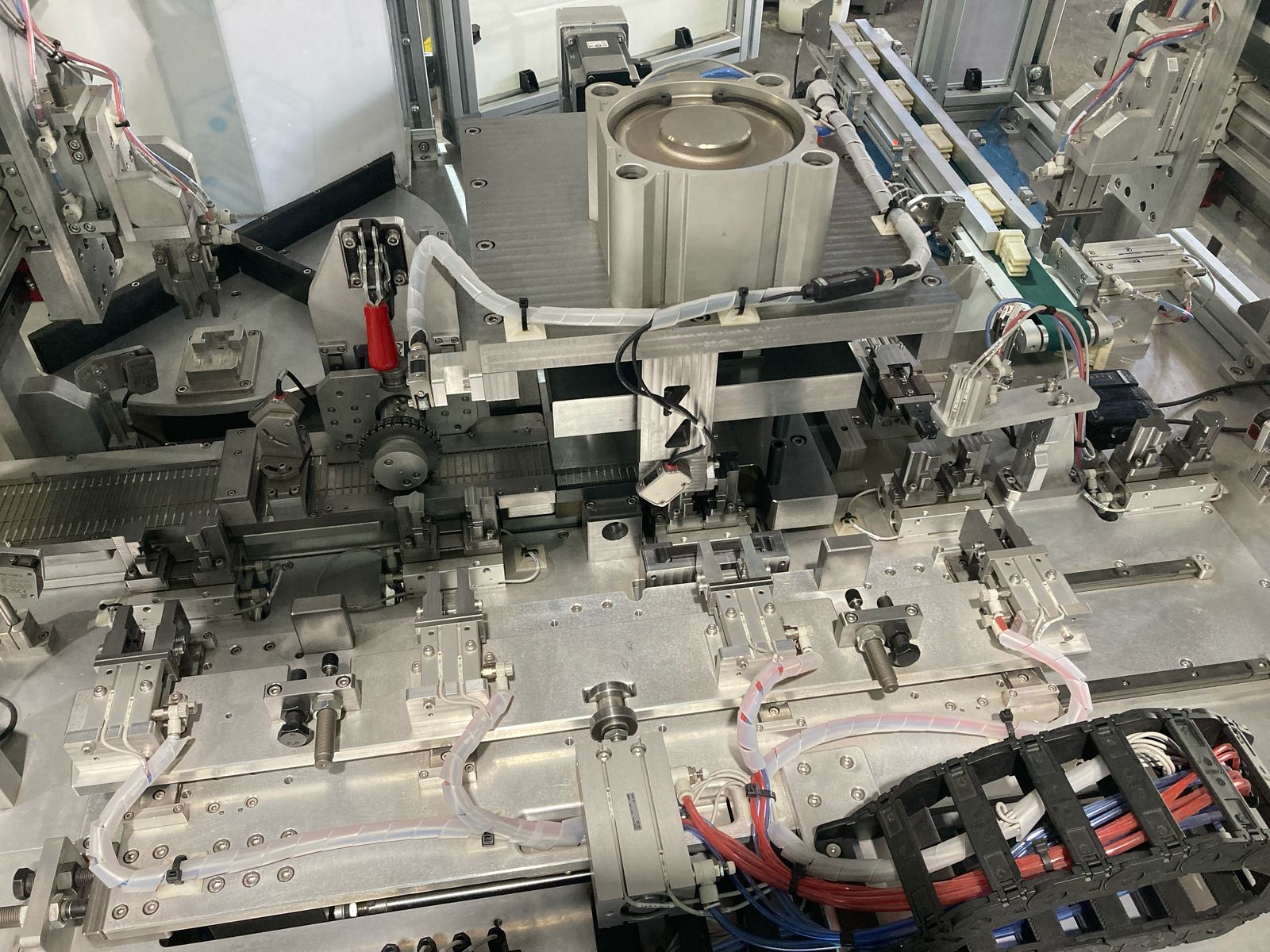

The MPP – Modular Pick and Place system developed by CIP optimizes assembly processes by reducing variability, material handling, and efficiency losses. This standardized solution improves productivity, stability, and operational flexibility, enabling the manufacturing of multiple products with fast, simple changeovers.

In HVIL assembly processes, the automation developed by CIP eliminated manual bottlenecks, increased production by 50%, and improved quality. The system integrates controlled insertion, automated inspection, and full traceability, delivering a robust, repeatable process aligned with automotive industry standards.

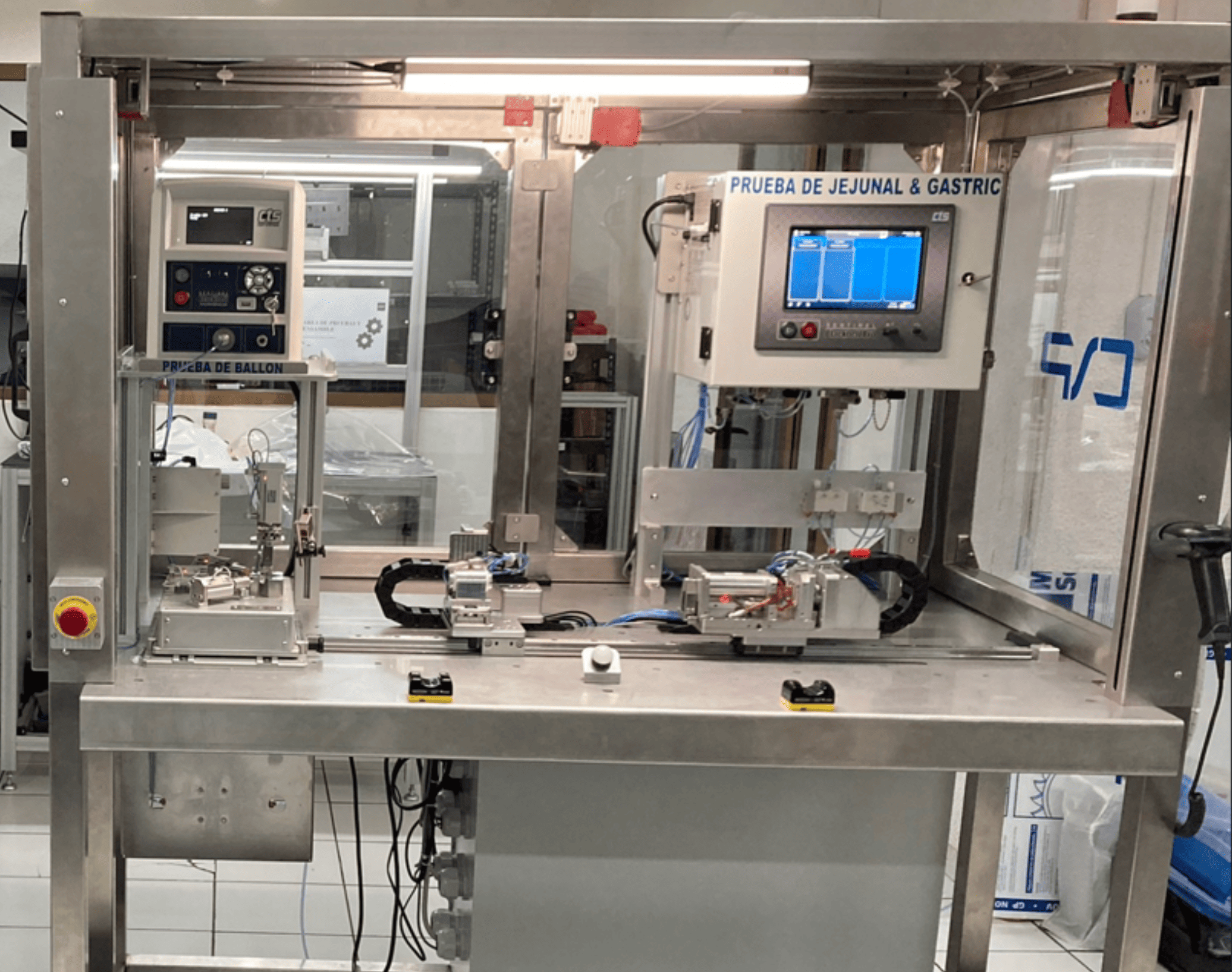

Manual final inspections limited defect detection and product validation. CIP’s automated EOL system integrated over 60 inspections, laser marking, and functional testing, significantly increasing process reliability. The result is a robust, repeatable, and fully automated system aligned with the highest industrial quality standards.

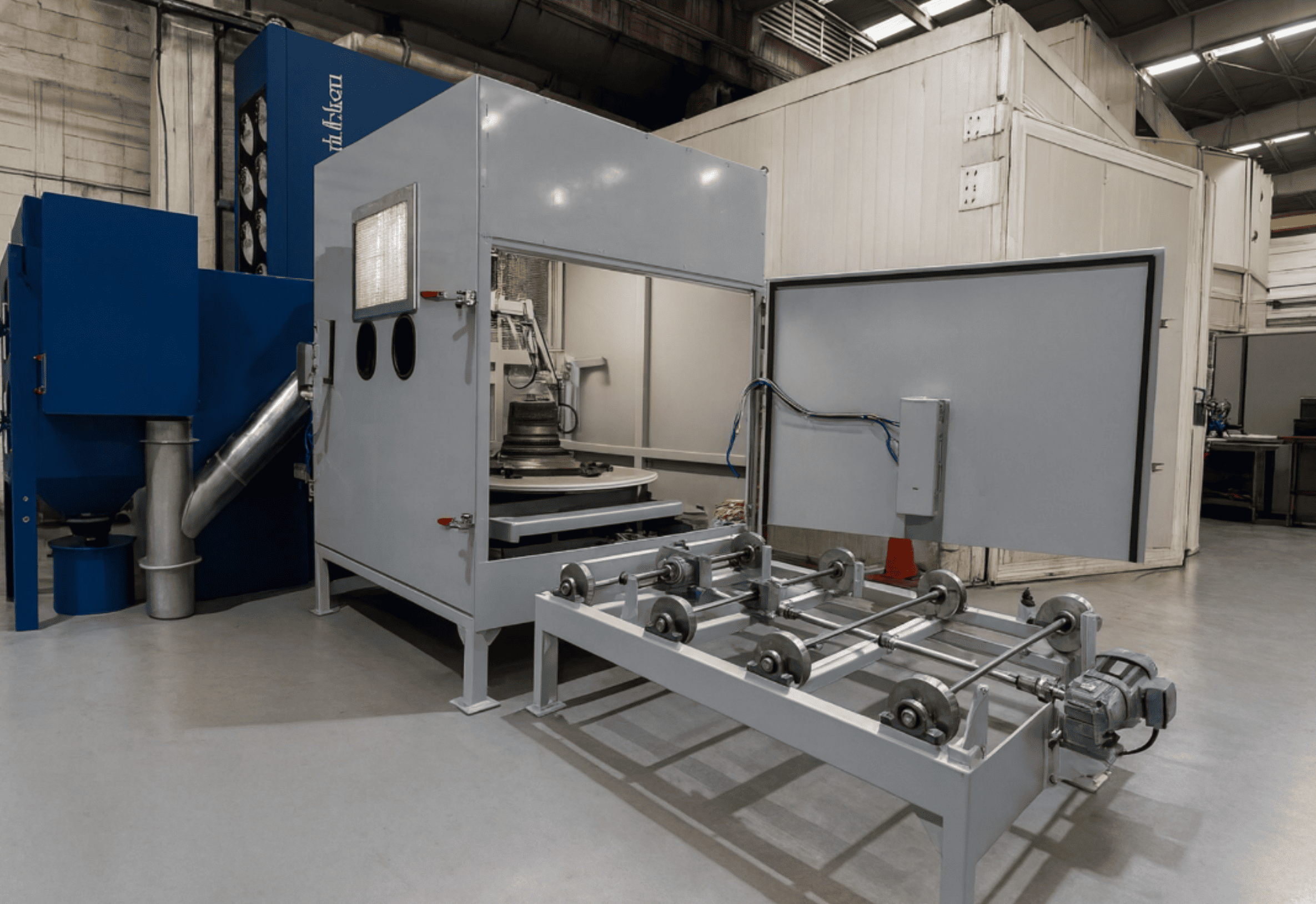

The customer faced operational limitations when processing small parts using conventional equipment. CIP, in collaboration with CA6s, developed a specialized booth with a motorized system and overhead crane. The solution optimized capacity, improved production flow, and significantly increased safety, resulting in a more efficient and controlled process.

The manual leak testing method limited precision and traceability. CIP developed an automated system with high-precision sensors, interchangeable fixtures, and an intelligent servomotor. The solution eliminated manual adjustments, enabled validation of multiple part numbers, and delivered quantifiable, repeatable results aligned with medical industry standards.

Growing demand exceeded the capacity of existing booths. CIP designed a customized arc spray booth with a rotary table for parts up to 5 tons, addressing challenges in fixturing, cable routing, and control integration. The result is a robust solution that increases capacity, safety, and operational efficiency.

The customer faced high complexity when producing multiple part numbers with varied processes. CIP developed a flexible assembly machine capable of handling over 250 part numbers. The solution standardized operations, reduced changeover times, and improved production flow, increasing capacity and responsiveness to demand.

The trust of our clients supports every project.

We worked with CIP on an assembly automation project, and the focus was very clear from the engineering phase. They delivered a stable, well-documented, and functional system right from start-up. Their experience in integration and commissioning is evident.

CIP quickly understood the real limitations of the process and proposed a viable solution without over-engineering. The team responded well regarding timelines and adjustments during implementation. Today, the system operates consistently and without rework.

The project required high precision and quality control. CIP met the technical standards and provided timely follow-up after start-up. They are a reliable partner for projects where there is no margin for error.