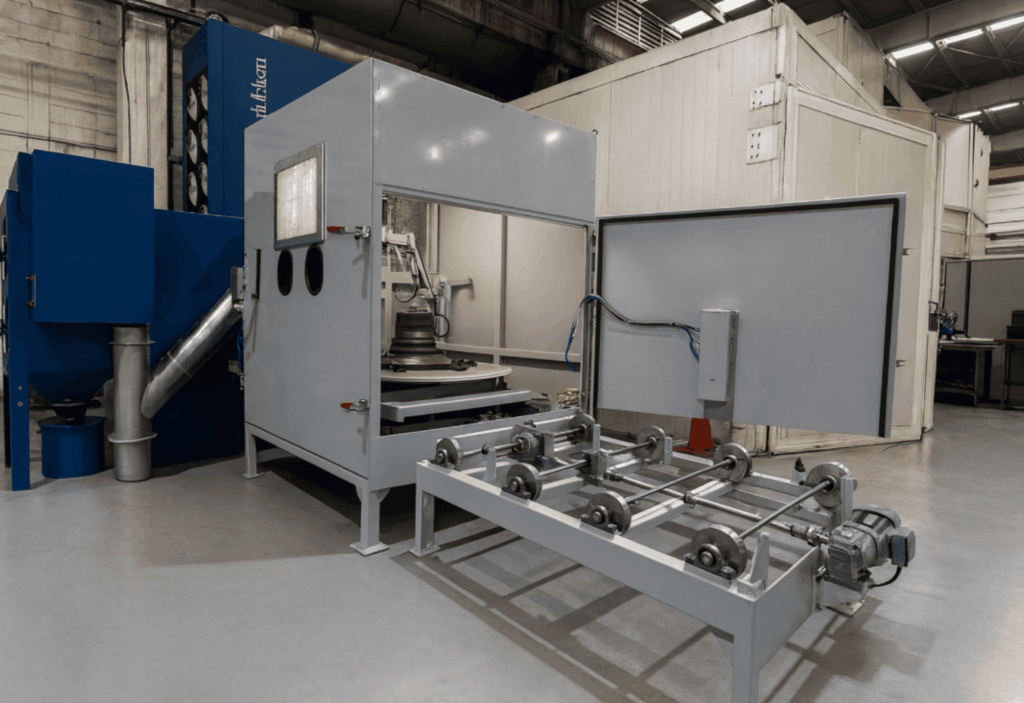

The customer was using conventional lathes and metallizing booths to process small parts, which reduced the available capacity for large parts and created operational limitations. CIP and in collaboration with CA6s We developed a specialized booth for small parts, designed to optimize capacity, safety and production flow.

Using an overhead crane and a motorized system that automatically feeds the workpiece into the booth, the operator remains in a safe zone without direct contact with the arc spray process.

The result is a more efficient, controlled, and significantly safer process, freeing up production capacity and increasing operational efficiency.

Turn your design into a real piece

Contact us to help you make your project a reality